Our Brewery

Macedonian Thrace Brewery has one of the most modern brewing facilities worldwide. The phrase of our founder, Demetri Politopoulos, “when something is born, it starts out small and grows with love" is our guiding principle. We remain committed to “growing with love” and honoring our devoted friends who choose our beers, by reinvesting our profits in the very best brewing and quality control equipment available, creating new jobs and supporting our local and national economy. Simultaneously, we add value to the products of Greek land and shape Greek beer culture for our country.

Environmental protection is a non-negotiable condition for our brewery and for this reason, we have managed to reduce water use at all stages of production, from sowing in the field to processing of the finished product. In addition, Macedonian Thrace Brewery, through the implementation of specific comprehensive recycling programs, contributes to the saving of raw materials and energy.

Environmental protection is a non-negotiable condition for our brewery and for this reason, we have managed to reduce water use at all stages of production, from sowing in the field to processing of the finished product. In addition, Macedonian Thrace Brewery, through the implementation of specific comprehensive recycling programs, contributes to the saving of raw materials and energy.

01. Mashing

The first step in the beer-making process is mashing, in which malt is steeped in hot water (70°C). Firstly, the malt is ground with the help of a grinder, immersed in hot water to produce fermentable sugars giving flavor and color to the water, which is now called wort.

02. Boiling and Cooling

At this stage, the solid malt is removed and the wort is boiled at 100 °C with the addition of hop, which will give the wort the desired bitterness and its characteristic aromas. Once the boiling process with hop's addition is completed, the beer wort, which is produced, is cooled with the help of cooling heat exchangers.

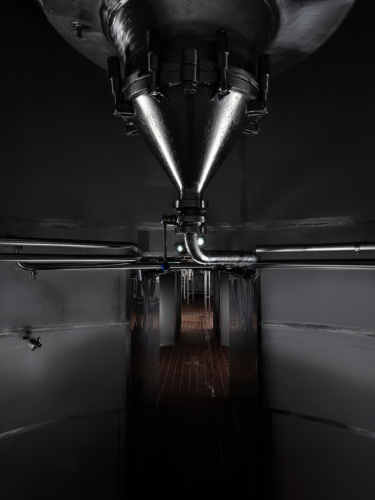

03. Fermentation

When the boiling stage is over, the wort is cooled via heat exchangers,and then stored into fermentation vessels where yeast is added to it. Yeast metabolizes the sugars contained in beer wort producing alcohol and carbon dioxide. The beer is stored in cold temperatures for 21 days (VERGINA Premium Lager & VERGINA Alcohol Free) whereas fermentation process lasts longer for the special beers of Macedonian Thrace Brewery.

04. Filtering and Bottling

Once fermentation is completed the beer is filtered. VERGINA Premium Lager, VERGINA Alcohol Free and VERGINA Red are filtered, while VERGINA Weiss, VERGINA Black, and VERGINA Porfyra contains their yeast. Filtering removes yeast residues, leaving the beer crystal clear and increasing its stability. The final step is bottling the beer in bottles or in aluminum cans and their pasteurization, not until the most strict quality controls have been carried out. All VERGINA beers, except VERGINA Alcohol Free and VERGINA Porphyra, are available fresh and unpasteurized in 20lt, 30lt and 50lt kegs depending on the beer type.